The use of technical ceramic materials in industry stems from their remarkable properties, such as high-temperature resistance, rigidity/weight ratio and durability.

At the end of the manufacturing process, it is important to check the finished product to guarantee its quality. To maintain the product’s level of performance in operation, it is imperative to extend the inspection of ceramic parts and detect any deterioration in their integrity at an early stage.

Defects in ceramic materials can be of various kinds, and Terahertz waves can detect the most common defects, such as :

- Foreign particles

- Lack of material

- Water content

- Dimensional measurements

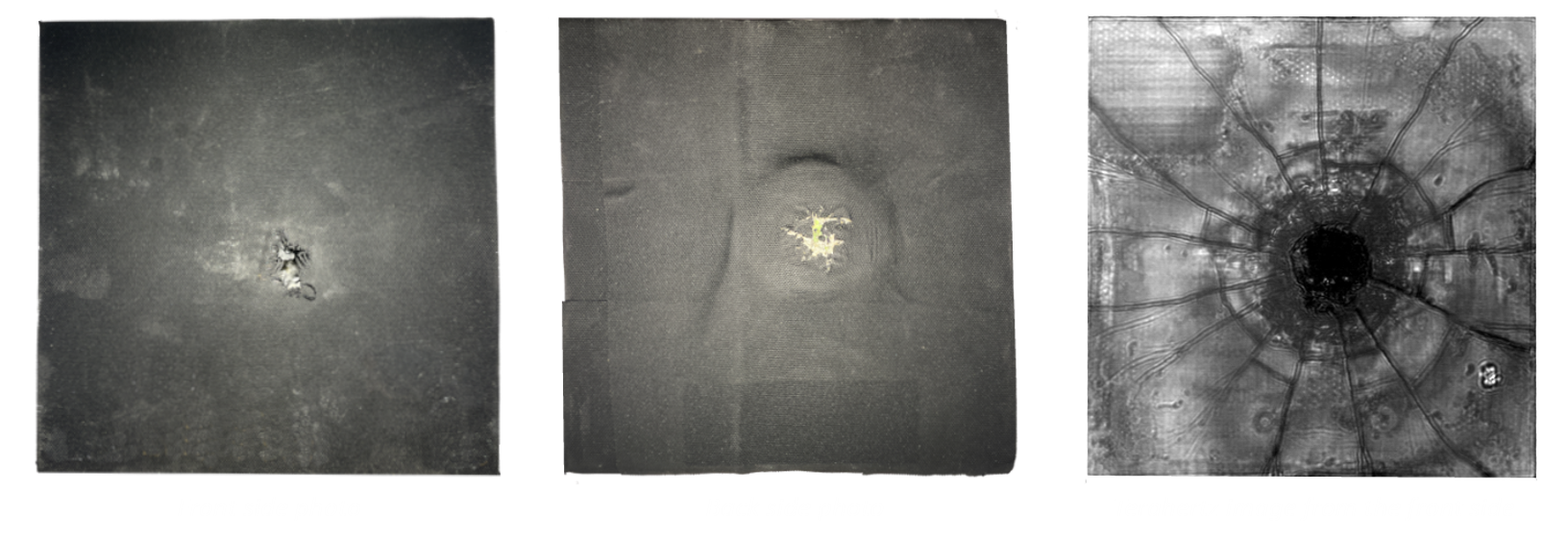

Example of a thick alumina plate (1cm) with metal plating on the back.

Before/After front side photo / TeraHertz image.

TeraHertz waves can be used to penetrate the coating to visualize the impact on the ceramic.

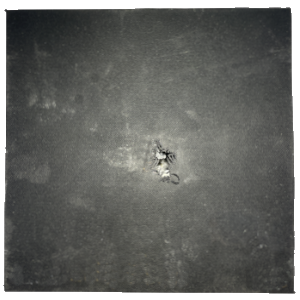

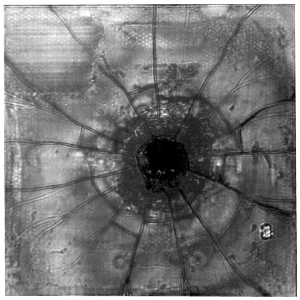

Example of a thick alumina plate (1cm) with metal plating on the back.

Before/After Front view photo / TeraHertz image.

TeraHertz waves can penetrate the entire thickness of the ceramic part and visualize the metal plating.