Polymer materials are becoming increasingly popular in industry thanks to their versatility, light weight and ease of manufacture. Their applications extend to a variety of sectors to meet the demands of performance, durability and recyclability.

During the sometimes complex phases of the manufacturing process, it is essential to monitor every stage of the production cycle to ensure the expected product quality. In order to maintain this level of performance in operation, it is imperative to extend the inspection of polymer parts and detect any deterioration in their integrity at an early stage.

Defects in composite materials can be of various kinds, and terahertz is capable of detecting the most common defects, such as :

- Foreign particles

- Lack of material

- Delamination

- Water content

- Dimensional measurements

a

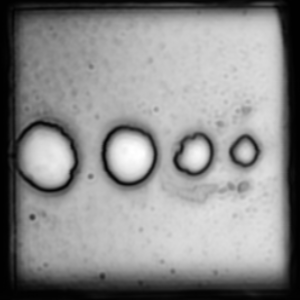

Example on a polypropylene sample on a metal substrate, observation of bonding defects (epoxy glue):

Before/After optical image front view / TeraHertz image -> circular areas = lack of glue