Composite materials are increasingly used in industry, thanks to their light weight, structural strength and adaptability. These innovative materials are favored in a variety of applications aimed at improving performance and reducing carbon footprints.

During their manufacturing process, which can be complex, it is crucial to be able to control every stage of the production cycle in order to guarantee the quality and performance expected of the products. To maintain this level of performance in operation, it is essential to continue inspecting composite parts to detect any changes in their integrity at an early stage.

Defects in composite materials can be of many different kinds, and Terahertz waves are capable of detecting the most common defects, such as :

- Foreign particles

- Impregnation

- Lack of material

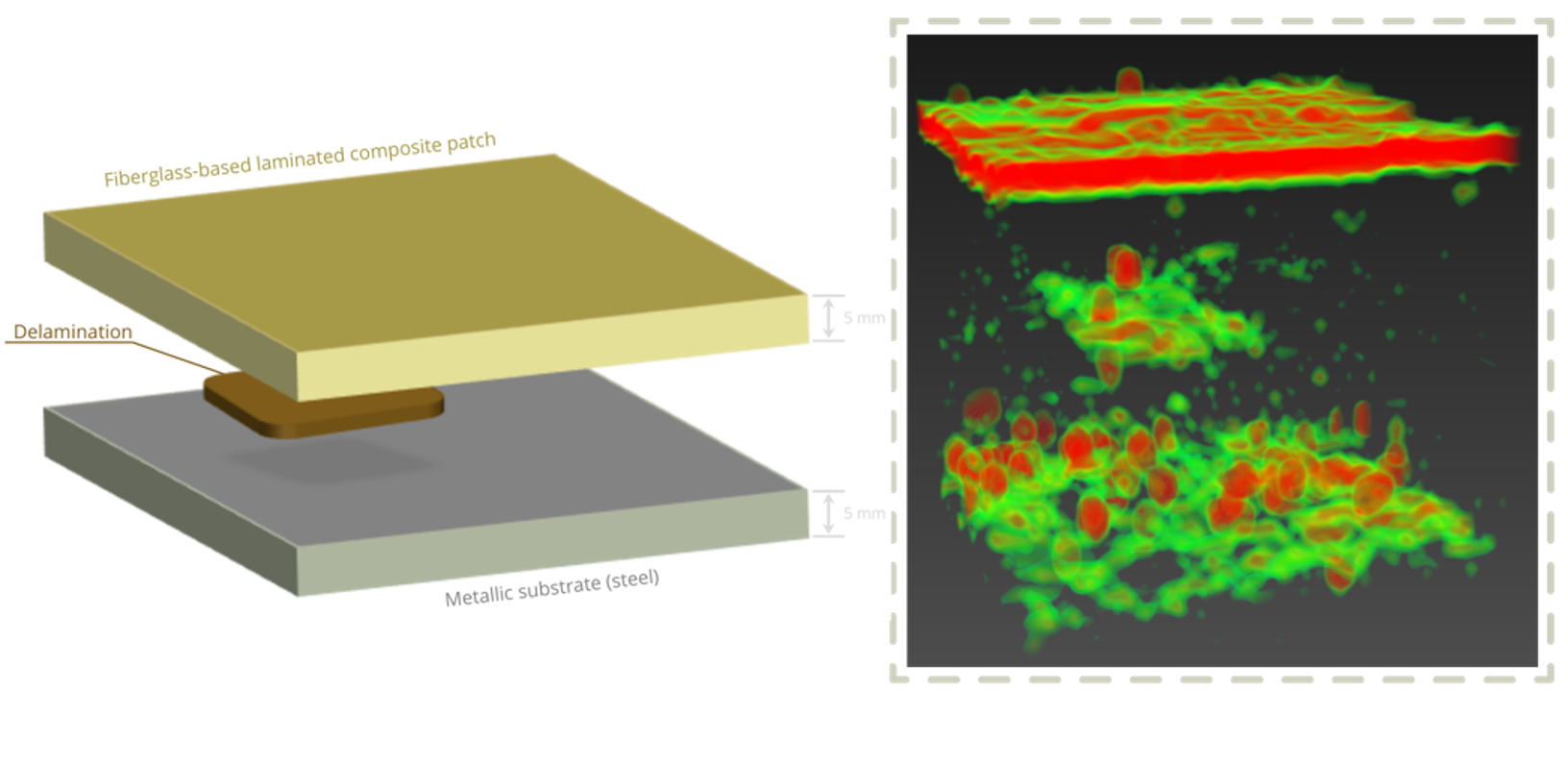

- Delamination

- Water content

- Dimensional measurements

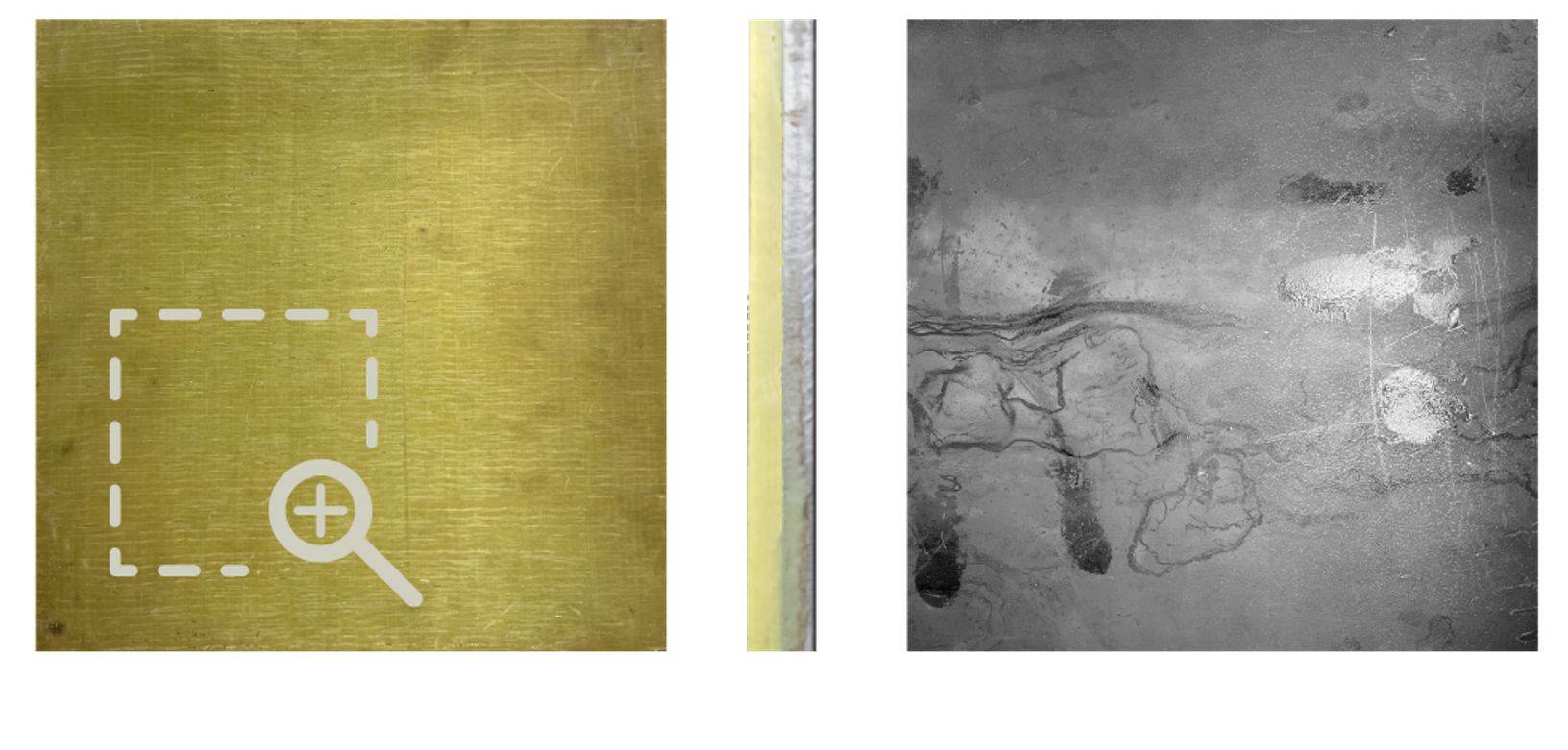

Example of a glass-fibre laminated composite patch on a metal substrate (steel):

a